Diaphragm Compressors

HOFER diaphragm compressors

HOFER diaphragm compressors provide a lubricant and technical abrasion-free compression of gases and gas mixtures.

Since they operate without leakage, they are particularly suitable for gases of highest purity as well as explosive, toxic and expensive gases. HOFER diaphragm compressors ensure a reliable compression of various gases such as hydrogen, helium, argon, ethylene, fluorine, hydrogen sulphide, chlorine, monosilane or nitrogen trifluoride.

HOFER diaphragm compressors are usually used for filling of storage vessels, for feeding into continuous processes or as gas circulating compressors.

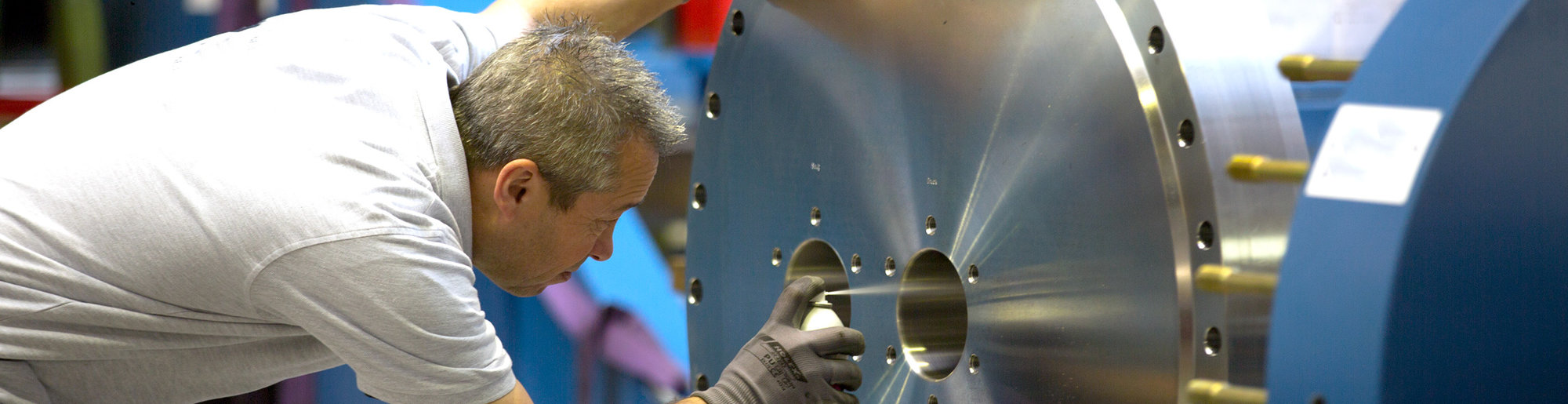

HOFER diaphragm compressors are characterized by their design that makes the machines exceptionally safe, reliable and easy to maintain.

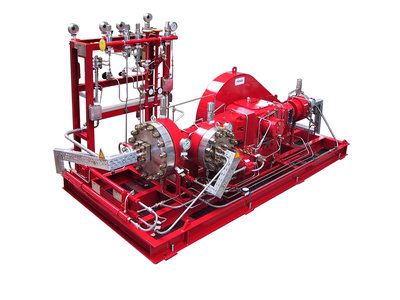

As a rule, we deliver our diaphragm compressors as complete units, including a base frame, a power unit, pulsation dampers, coolers, automatically- or manually-operated valves, instruments and, if requested, a control unit. Optionally, we also supply diaphragm compressors without peripheral equipment ready to be installed in your system.

All HOFER diaphragm compressors are subjected to a test run under load at our factory, during which the operating data are recorded and documented.

- oil-free compression due to hermetic separation between gas and oil chamber

- technical abrasion-free compression due to static seals in the gas stream

- leakage rates of 10^-4 mbar l/sec (on request up to 10^-6 mbar l/sec)

- purge or buffer gas is not required

- long service life because of a hydraulically actuated diaphragm, no mechanical linkage

- good cooling due to the large surface of the diaphragm head

- cooling coil in the oil chamber of the diaphragm head, no weakening of the cover caused by cooling channels

- automatic shutdown in case of a diaphragm failure prevents consequential damage

- discharge pressure up to 43,511 psi (3,000 bar)

- stage pressure ratios up to 7

- up to 4 stages at a crank drive

- mass compensation for foundation-free installation

- wear resistant and smooth operation due to low piston speeds

- water cooling provides the best cooling effect as well as a low sound pressure level

- manufactured in compliance with 2006/42/EC EC-Machinery Directive. Applied standards: DIN EN 1012 part 1, DIN EN 12100 part 1, DIN EN 60204 part 1 et al.

- explosion proof according to the European Directive 2014/34/EU, if necessary

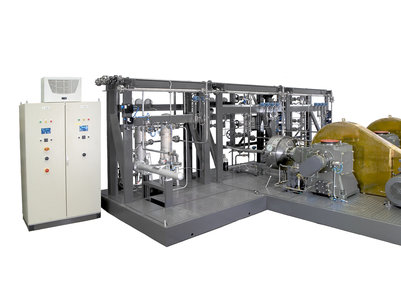

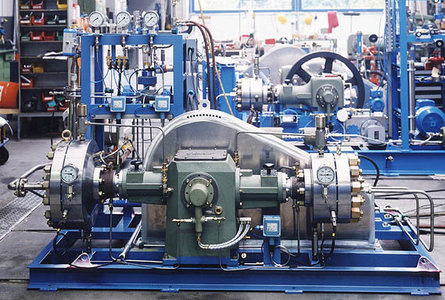

Diaphragm Compressor

MKZ 560-15

Two compressors. One compressor in operation, the second compressor on standby

490 Nm3 / h

H2

410 psi (28 bar abs)

1,410 psi (97 bar abs)

Valve and instrumentation panel

Flow control valve for each of the two compressors. All valves are bellows-sealed type.Pressure line for suction- and intermediate pressure with block & bleed valves.

Discharge pressure line with double block & bleed valves.

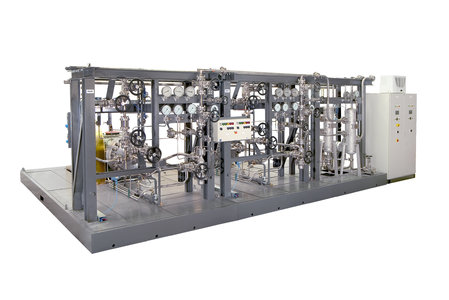

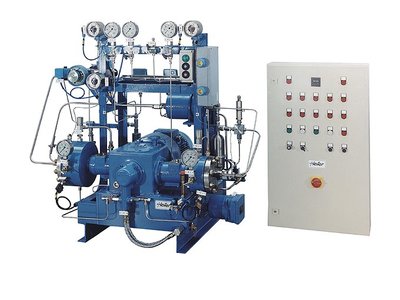

Diaphragm Compressor

MKZ 710-5/450-15

Two compressors. One compressor in operation, the second compressor on standby

390 Nm3 / h

H2

130 psi (9 bar abs)

1,410 psi (97 bar abs)

Valve and instrumentation panel

Flow control valve for each of the two compressors. All valves are bellows-sealed type.Pressure line for suction- and intermediate pressure with block & bleed valves.

Discharge pressure line with double block & bleed valves.

Diaphragm Compressor

MKZ 400-10/250-25/160-60

72 Nm3 / h

Ar/O2 gas mixture

190 psi (13 bar abs)

8,700 psi (600 bar abs)

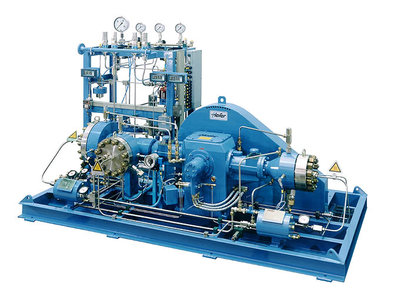

Diaphragm Compressor

MKZ 500-10/400-25

450 Nm3 / h

H2

380 psi (26.2 bar abs)

2,620 psi (180.4 bar abs)

Diaphragm Compressor

MKZ 300-5/200-40

27,5 Nm3 / h

propane/H2-mixture

70 psi (5 bar)

4,350 psi (300 bar)

Diaphragm Compressor

MKZ 185-5/120-15

5,5 Nm3 / h

H2

70 psi (5 bar)

2,190 psi (151 bar)

Diaphragm Compressor

MKZ 560-5/350-25 / MKZ 200-70

142 Nm3 / h

Ar-O2-He-mixture

135/2,920 psi (9.3/201 bar)

2,920/9,010 psi (201/621 bar)

Diaphragm Compressor

MKZ450-10/280-25

112 Nm3 / h

H2

160 psi (11 bar)

3,640 psi (251 bar)

Diaphragm Compressor

MKZ 280-10/185-25/120-100

20 Nm3 / h

He

115 psi (8 bar)

12,750 psi (880 bar)

Diaphragm Compressor

MKZ 860-2/470-10/315-25

80 Nm3 / h

He

15 psi (1.03 bar abs)

3,420 psi (236 bar abs)

Diaphragm Compressor

MKZ 680-10/450-40

581 Nm3 / h

H2

260 psi (18 bar abs)

4,075 psi (281 bar abs)