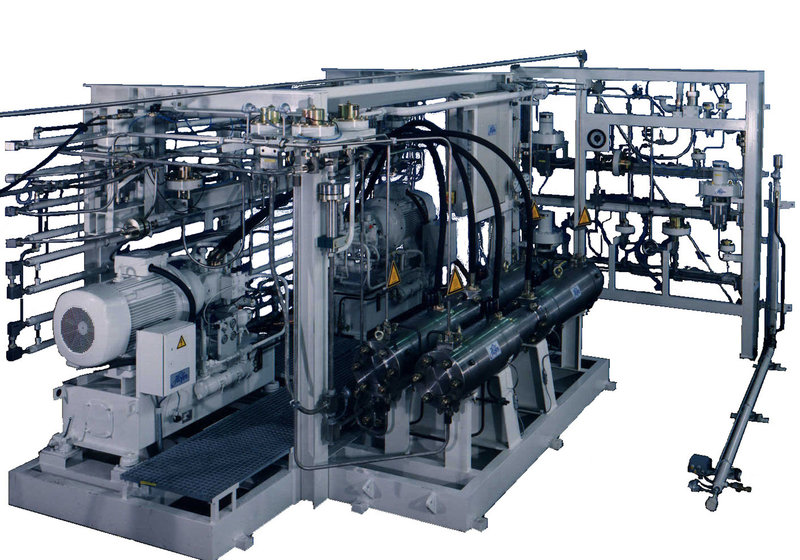

Hot isostatic pressing machines (HIP)

Hot isostatic pressing machines

With the HIP process, metal powder or preformed parts are solidified and sintered under high gas pressure. Cast components can be "hipped" with this process and obtain special properties with regard to strength and homogeneity.

Metal powder is filled into steel tubes with a bottom, compressed and the tube is welded with a lid. These tubes are placed in a pressure vessel which is sealed. The internal heating system in line with the HOFER TKH compressing the argon up to 1,000 and 2,300 bar, the gas will be heated up to 2,000°C. Under this pressure and temperature, the metal powder sinters into a solid block, which is then peeled out of the steel tube after being removed from the pressure vessel and cooled. Afterwards, the new material can be further processed using conventional methods. The technological properties of the sintering block can be designed by mixing the metal powder. This process can also be used to sinter pre-pressed components such as turbine blades or artificial hip joints to a perfect fit.